and its processing cautions/problems…

If you grew up watching Phineas and Ferb like I did (am I speaking to the right audience?), you probably learned what aglet, the hard tip of the shoelace, was with the A-G-L-E-T song. Well, we can actually arrange aglet processing for you for most of the cords.

Of course, there are metal and plastic tips, but today, I will talk about the plastic tip processing lead times, and issues that may come up with it.

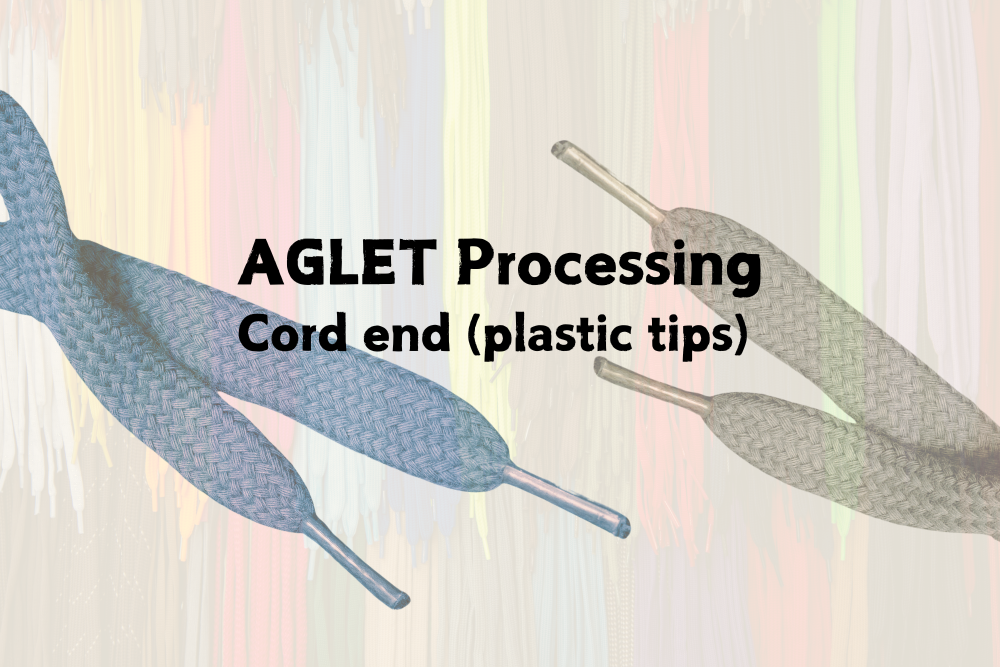

What is Aglet (plastic tip) processing?

An aglet is made by wrapping a cord in transparent tape and pressing it together with heat. It is processed using a special machine, often used on the ends of shoelaces and hoodie laces.

Clear tips can be requested to most cord/tape manufacturer that you are buying the cord or tape from.

The color of the tips may vary depending on the manufacturer, but in some cases you may be able to bring in your own string and have it processed.

Lead time

For samples, it will take a few days to a week.

Mass production can take anywhere from 10 days to 2 weeks (depending on the number of items and the workload of the factory at the time of request).

Types of cell chips – colors available too –

Unless otherwise specified, aglets will be assumed and processed with clear plastic (transparent).

They are available in black, and some manufacturers offer them in other colors and patterns.

Please give us instructions to forward to manufacturer if desired.

SHINDO – aglet processing

ROSE BRAND – aglet processing

Cordon – aglet processing

Cordon has a wide variety of chips. Pay attention to the instructions.

(left to right: Plastic tip, Long plastic tip, color plastic tip, and eco tip)

↑Color cell chip

Custom logo/icon prints on your aglet

You can have your aglet customised with your logo or icons.

It’s quite a high hurdle with the large MOQ quantity and long lead times…

From the SHINDO website…

You can create your own original cell chip by printing your brand logo, icon, or pattern.

Here is an example of SIC (SHINDO).

MOQ: 400 pieces or more

Cell color: Transparent only.

Color cells cannot be used as the print is printed on the inside of the cell to prevent it from coming off due to friction.

Cost:

Data cost: Several ten thousand yen (¥10,000= abt. $65 USD) (price varies depending on the pattern. It will be more expensive for detailed patterns or many characters.)

Aglet cost: Several ten thousand yen (it will be cheaper if you make a lot.)

Processing cost: From several ten yen (couple cents per tip) (separate from the string/cord cost. If you make less than 100 pieces of one specification, an additonal small-batch processing fee will be charged.)

Creation process

Design: Select the cord and create design

**Thin/small text cannot be printed and the character count must be around 5 characters.

Share design with Manufacturer: Handwritten design is fine, but digital/technical data will be cheaper.

Print data creation – Confirm the Print Data

Plastic printing: If the print block copy data is OK, it will be printed on the plastic. In the case of logos, etc., it is easier to convey the print pitch if you choose a standard cord thickness. In some cases, it may be possible to create a sample, but there may be an additional sample fee.

Lead Time: The lead time for the 400 is about 1 to 2 months.

[Example of trouble] When aglet processing a round rubber cord, the tip became bent.

Once, when someone sent a round rubber band cord for tip processing, it came out quite bent.

“It looks just like a garden eel!”

When we requested a sample before production, it wasn’t bent that much, so we asked the processing plant why this occurred. They told us

that because the material is stretched before it is put through the machine, it can sometimes shrink before it cools down and hardens.

It’s hard to say that this won’t happen again…

This was a custom-made item with a silicone end placed on top, so we managed to get it to work in the end.

For the next order, we asked them to be as careful as possible before requesting the processing, and they delivered it without bending it too much, but we still think that luck played a large role.

!Notice!

When requesting aglet processing of round rubber bands, please consider the risk that the tip may bend .

Due to its stretchy nature, there is often considerable variation in length.

Some manufacturers do not accept cell chip processing of round rubber bands (Cordon), so I don’t think it’s advisable to request aglet processing of round rubber bands.

Conclusion

I thought that aglet processing could be done on any cord/string, so I learned that problems like this can occur when creating tips for round rubber band cords.

By the way, it seems that the metal tip of round rubber band cords can sometimes come off. yikes…

Troubles are inevitable with custom-made products, so please make sure you give yourself plenty of time when ordering.

Hope this was helpful and informative!

ApparelX is a BtoB ecommerce platform for brands, tailors and the like to order from small MOQs from a variety of manufacturers in one order. And we ship worldwide!

Check out our FAQ page, Youtube, and LinkedIn if you have basic questions or looking to stay connected.

If you are looking to bulk order, custom order, or have any other questions, contact us through our contact form and a member on the Global Strategy Team will get back to you within the next business day. (Please understand that we are based in Japan and our office hours are 9am-6pm so we are only able to answer during that time).